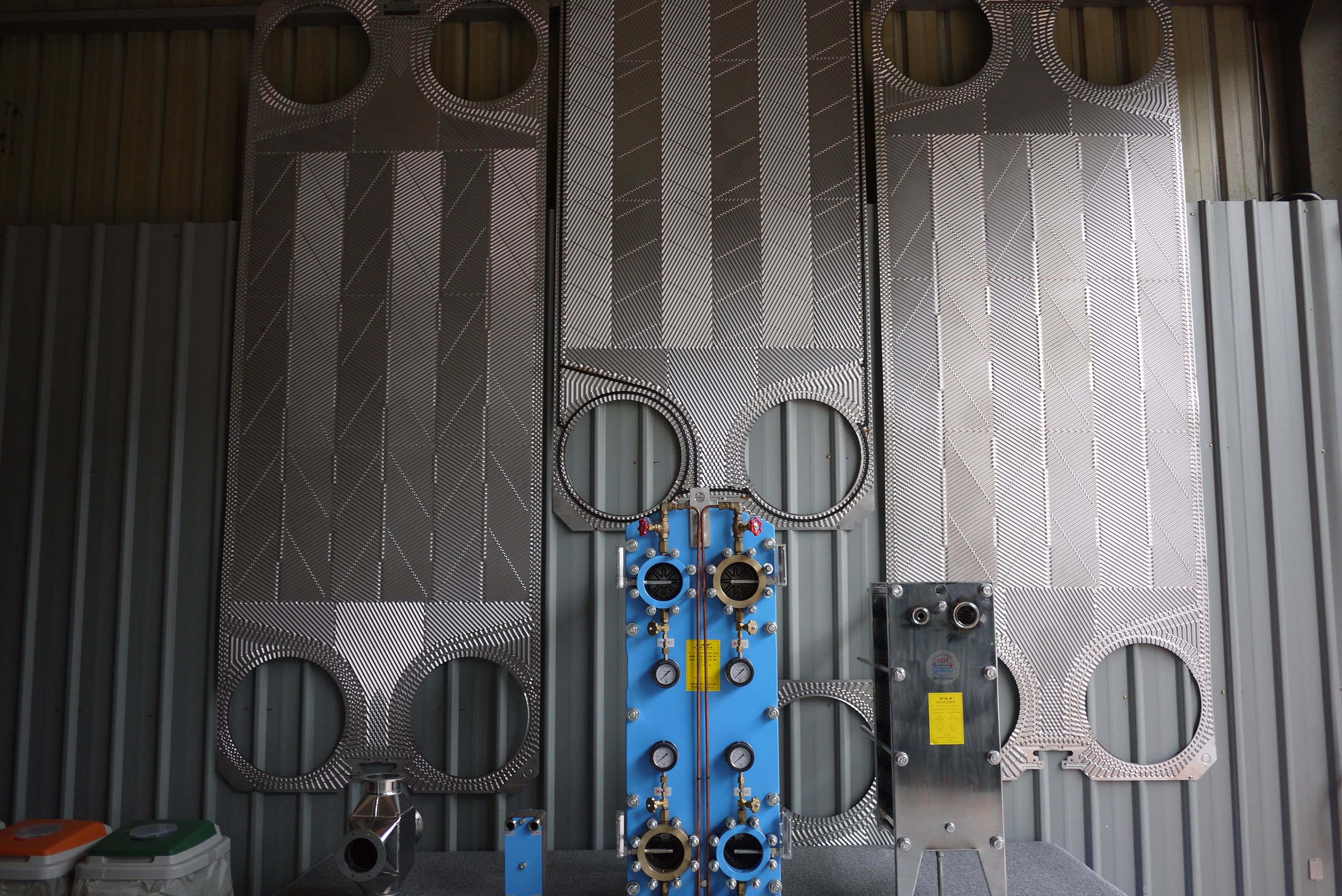

SRP Gasketed Plate Heat Exchangers

heat exchanger gaskets manufacturer

Compact thermally efficient solutions

The main advantage of a gasketed plate heat exchanger is that it is can easily be removed for replacing, cleaning, and maintenance purposes. It also allows extra plates to be added when your process conditions change.

SRP Gasketed Plate Heat Exchangers are manufactured in our own factory from stock components. It means that we can delivery fully tested and assembled units quickly.

Advantages of our Gasketed Plate Heat Exchangers

Gasketed plate heat exchanger are a good choice mainly due to the compact size and high efficiency design that it offers.

- High thermal efficiency

- Suitable for industrial applications

- De-mountable for cleaning and maintenance

- Compact design

- Suitable for use with steam

- Can have additional heat transfer plates added if required

SRP supplys Gasketed Plate Heat Exchangers for many industries:

- Heat pump installations

- Industrial process liquid heating and cooling system

- Pharmaceutical - water heating / cooling

- Brewing - Wort cooling(beer/lager/cider)

- Marine - for uses such as main engine cooling, oil cooling, and deck wash water heating

- Chemical heating and cooling

- Heating, Ventilating & Air Conditioning

- Boiler separation plates

Material Options for Gasketed Plate Heat Exchanger

- Connections: BSP threaded / Flanged / Hygienic

- Standard Plates: Titanium / Hastelloy / 316 and 304 Stainless Steel

- Gaskets: All gaskets are clip-on type

Replacement parts of our products

- SRP can supply parts on their own or fitted as part of a service.

- Big range of spare parts available in stock at our factory.