Setup in year 1992 by Sweden Swep International AB Separted with Swep in Year 2007. 100% heat exchanger Supplier in Taiwan. Main heat exchanger factory in Taiwan, Also Beijing and Shanghai. 2015 New heat exchanger factory in Germany. 6 Press and two laser welding machine. We offer compact heat transfer solutions and service worldwide. Best plate heat exchanger manufacturer and supplier!

Applicable for high-temperature and high-pressure systems

Make by SRP Germany Factory

In addition to the combination of merits of Plate Heat Exchangers: small footprint, extremely high heat transfer efficiency, and scales prevention by reverse flow; and merits of Shell and tube Heat Exchangers: high-pressure and high-temperature resistance; Shell & Plate Heat Exchanger is a new model that also features higher safety and stability altogether.

Next Generation Data Center Cooling System

Real World Two Phase Cooling

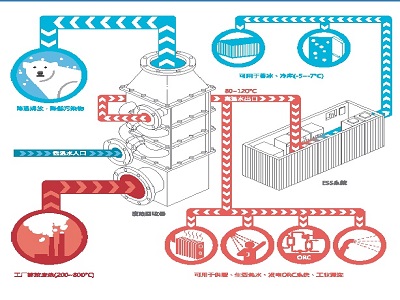

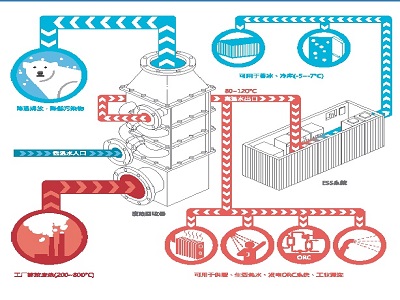

Absorption System , Not Compressor

Saving Energy

E.G Water outlet to -5 C ~ - 7 C

Suitable for Ice storage system and also Supermarker

Absorption System , Not Compressor

Saving Energy

E.G Water outlet to -5 C ~ - 7 C

Suitable for Ice storage system and also Supermarker

Next Generation Data Center Cooling System

Real World Two Phase Cooling

90% Engergy efficiency improvement over air conditioning

Up to 70% Floor Space Savings

Manufature, After service any time & any place.

Taiwan SRP Heat Exchanger Inc. is the best heat exchanger manufacturer expertising in various type of advanced heat transfer machines.

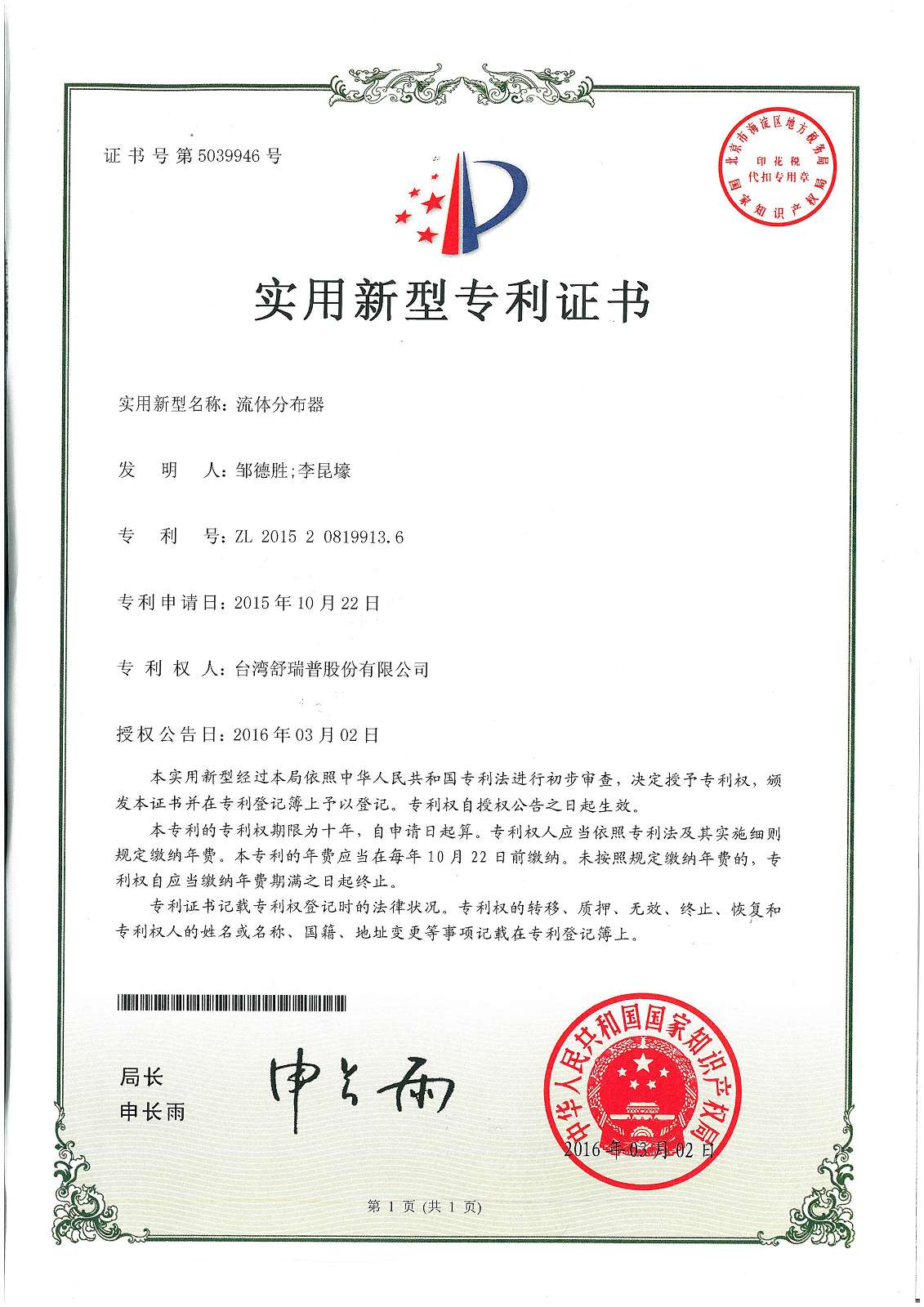

Our New Gas Heat Exchanger distributor got new patent aproval by China government. It's our No.4 patent for heat exchanger.

We are still waiting a new apply Dimple plate patent from China and Europe government.(a total different plate compare with old herringbone plate)

This all 316L Stainless steel gas / liquid heat exchanger can take care 12,000 CMH air volume and pressure drop less than 800 Pa. It's our first step for this chemical giant in the world after few hundred similar unit installed.

We got En3834-3 approval for our Gas - Liquid / Gas - Gas plate type heat exchanger and also Sub-station unit.

Our product lines includes plate heat exchangers, shell and tube heat exchangers, stainless steel gas / liquid heat exchanger, gasket plate heat exchanger.

SRP offer a wide range of gasketed,Semi-Welding Gasket,Shell plate heat exchangers and Gas to Gas,Gas to Liquid Heat Exchanger. The products provide compact efficient solutions to your heat transfer requirements and are suited for many applications. Various heat exchangers sizes and modules are available from stock.

The invented heat exchanging device has unique features and qualities while exchanging heat.

Taiwan (May 25, 2016) – Taiwan SRP Heat Exchanger Inc. has invented a cutting-edge heat exchanging plate that can be used in various kinds of modern equipment used hugely in the recent times. The heat exchanging device is widely used in transferring heat from one liquid to other or one region to other. The widely used devices are refrigeration system, natural gas processing, thermal power stations, air-conditioning, chemical plants, sewage treatment, petroleum refineries systems, etc. An improved heat sinking device transfers heat very smoothly from one fluid to another; then there is no use of ordinary heat sinking device lasting comparatively lesser than the heat exchanging device is invented by this company.

The invented heat exchanging device has unique features and qualities while exchanging heat. Basically, the exchanger works between two fluid, gas or hard substance. Two fluids or gasses can be kept separate from mixing together, but one heating device can make them warm similarly. The effective feature of a heat exchanging gasket is to transfer heat without transferring the fluid of gas carrying heat.

The features of the gasket that attract most is that the heat exchanging device made by Taiwan SRP Heat Exchanger Inc., the superior quality heat exchanger gasket manufacturer and worldwide is thinner but wider. This enhances the flow of smooth heat transfer from one fluid or gas to other. For having a large surface, the exchanging device easily transfers heat without wasting a little. The process also becomes fast for all the related purposes.

Improved and advanced brazing technology has made the plate heat exchanger increasingly practical and useful. The fuel for heating the plate also will be less for the heat gets exchanged if a least is produced.

Transport(Automotive) and Marine:SRP offers a wide range of highly efficient integrated, compact cooling solutions for marine engine, automotive, vehicles, train, and other transport applications. Our robust and compact brazed plate heat exchangers are designed to maximize the cooling requirements and provide the most effective solution. Further more the light weight feature make SRP plate heat exchanger easy and quick to cleaning, maintenance, and inspection. We have ability to customize the product you want.

Heat exchangers in power plants and energy industry:SRP heat exchangers are designed to help make power generation more efficient. SRP is heat exchanger expert in the design and manufacturing of compact and reliable sub systems in power plants. The systems are customzable and designed to meet all your requirements. SRP is the ideal heat transfer choice in power generation application. From design , manufacture to test, We provide you a total solutions and after-services.

SRP Heat exchanger in district energy:SRP cost-effective system(Energy Saving System) give more stable control and better cooling. All the heat exchangers parts are factory assembled and the function is tested. Our products are designed to ensure high performance and service life of the components. Further more SRP system is developed in accordance with current heat exchanger standards. We provide an efficient solution for you.

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Plate heat exchangers are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, whereas smaller versions tend to be brazed.

The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger.

The plate heat exchanger (PHE) was invented by Dr Richard Seligman in 1923 and revolutionised methods of indirect heating and cooling of fluids. Dr Richard Seligman founded APV in 1910 as the Aluminium Plant & Vessel Company Limited, a specialist fabricating firm supplying welded vessels to the brewery and vegetable oil trades.

Plate heat exchangers, often called plate-and-frame heat exchanger, have a major advantage over( high heat transfer rate) other types of heat exchangers in that the fluids are exposed to a much larger surface area. The plate heat exchanger consists of a frame with end plates which squeeze the corrugated heat transfer plates. Within plate heat exchangers, the fluid paths alternate between plates allowing the two fluids to interact(heat or cool one fluid by transferring heat between it and another fluid, but not mix).

Plate Heat Exchangers have various applications-

- petrochemical

- pharmaceutical

- power

- industrial dairy

- chemical

- food and beverage industry

Taiwan SRP Heat Exchangers Inc. (台灣舒瑞普) collaborated with ITRI (Industrial Technology Research Institute, 工業技術研究院) to develop.

- The first Laser welding system for shell and plate heat exchanger in Taiwan.

- Heat exchanger process: "Multilayer laser welding" and "Laser seam welding"

- Mechanism of heat exchanger process

- Laser seam welding

- Weld tracking set up and optimize

- Optimize and monitoring for real-time weld process tracking

- Welding quality

- Flat and bright weld bead

- Well metallography welding for arc shape

- 0.5T + 0.5T plate full welding

- Weld porosity < 5%

- Automated laser welding increase 3 times yield

- The metallographic of welding quality

- SRP expertise in the design and manufacturing of shell and plate heat exchanger from case design and manufacturing

- Plate stamping

- ITRI assisted to integrate laser welding technology

- Assembly and install

- Pressure resistance > 150 bar, working temperature from -30℃ up to 900℃, highly corrosion resistance (for seawater, sulfuric acid, sulfide)

- Successfully applied in chemical production line

- Customers through all Europe, United States, Japan, Korea, China, Australia and most Southeast Asian countries

- The only company in Taiwan has the ability to design and manufacture shell and plate heat exchangers