Taiwan SRP Semi-Welding Gasket Plate Heat Exchanger - Introduction

General plate-type heat exchangers use rubber seals to stop the fluid. However, for an ammonia system, or for special hazardous or high-pressure fluids like refrigerant or toluene where a rubber gasket is not applicable, the gasket will be unable to fully seal the fluid due to its physical properties. Leakage in such applications will cause industrial incidents.

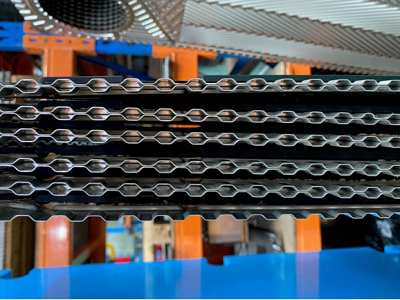

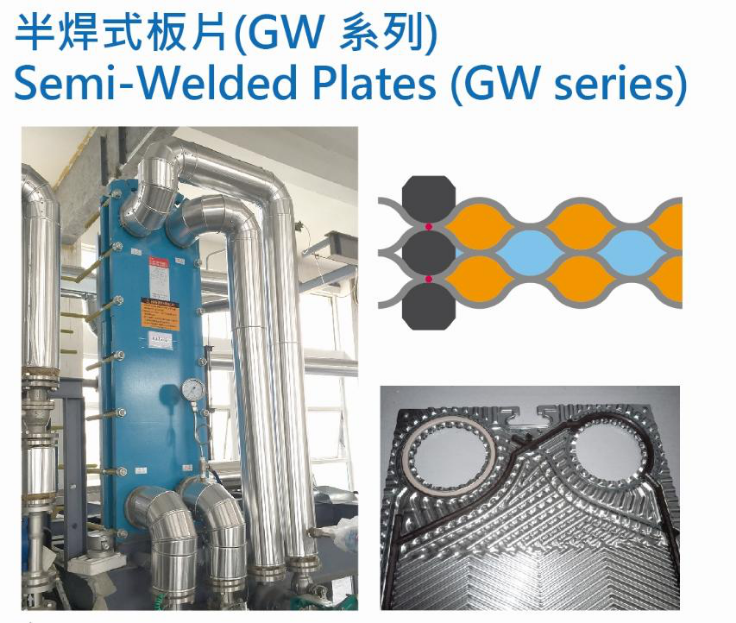

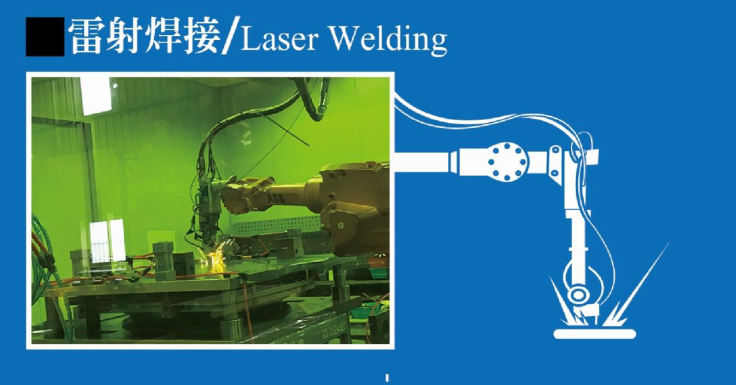

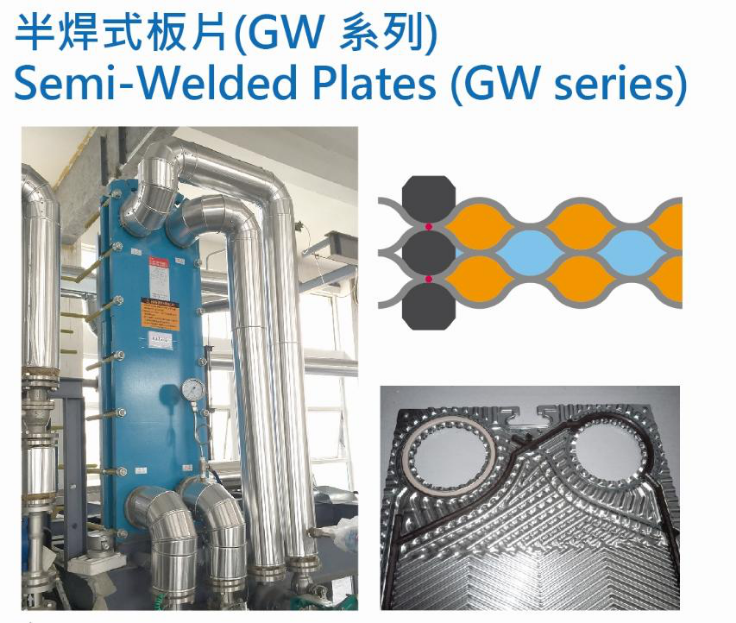

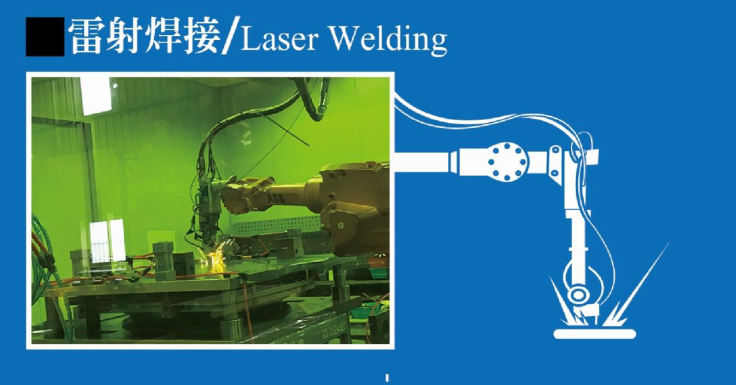

Taiwan SRP Inc. provides Semi-welded Plate Heat Exchangers to cope with these harsh conditions. Two metal base plates are welded together with special laser technology to form a honeycomb plate-set. The special high-pressure fluid is only transferred within the plate-set; gaskets in contact with the fluid are made of special rubber. An external metal frame is further provided to shield the heat exchanger so that the hazardous fluid is safely insolated without risks.

Features of SRP Semi-welded Gasket Plate Heat Exchangers

- Excellent sealing property; pressure bearing capability much higher than normal plate heat exchangers. Work pressure can be as high as 25~30 BAR.

- Plates are welded with special laser technology to ensure safety and leakage free of high-pressure fluids.

- Applicable to production processes using high-pressure and hazardous fluids in industries relating to food processing, refrigeration, air-conditioning, high-temperature boiler, and high-temperature steam applications.

- Lightweight product with a small footprint.

- Simple and convenient structure facilitates maintenance and installation.

- High efficiency heat exchange; uneasy to accumulate dirt or get clogged.

- Can be used as an evaporator, condenser, chiller or heater.

- Normal materials are SS304 and SS316L; also can be made of special metals such as /SS317/SS310/SS904/SMO254/ Hastelloy C276,Ti,Ti-PD, etc.

- The product is compact in structure and strong in corrosion resistance.

- Long service lifespan. Product has reserved space for expansion/curtailment of plates based on actual needs.

- Versatile gasket alternatives include NBR,EPDM, CR, and PTEF for optimal selection based on customer fluids, ensuring leak-free stay of fluid inside the heat exchanger.

- Wide product line ranging from DN100 (4”) to DN150 (6”) for respective port diameters used by customers.

- Applicable to highly corrosive fluids (e.g. Sulfuric acid).

- Made in Taiwan, short delivery time ensured.

- Strict quality control of products and a well-experienced after-sales service team allow for shortened maintenance time.

Since its establishment in 1992, Taiwan SRP Inc. has been deeply devoted to servicing Taiwan and overseas markets with plate heat exchangers.

With integrated operation procedures, we offer comprehensive, professional and prompt services, including order reception, interview, delivery, as well as subsequent maintenance and repair.

Taiwan SRP Inc. holds certifications including USA ASME U Stamp, EU Pressure Equipment Directive (PED), American Bureau of Shipping (ABS), Det Norske Veritas Germanischer Lloyd (DNV/GL), Bureau Veritas (BV), China Classification Society (CCS) & China Corporation Register of Shipping (CR) of Taiwan, Lloyds ISO 9001-2015, and EU Welding Certification EN3834-3.

Taiwan Type-I Pressure Vessel Codes and multiple international specifications are used for complying with review requirements and ensuring customer safety when using the device.

In recent years, for preventing industrial incidents, the government and labor inspection units tightened inspection of pressure vessel specifications and on-site installations, with relevant statutes and penalty regulations proclaimed more clearly. Taiwan SRP Inc. is one of a few heat exchanger manufacturers in Taiwan qualified for applying certificates of high-pressure gases and Type-I high-pressure vessels.

Customer Benefits through the use of SRP Semi-welded Gasket Plate Heat Exchangers

- Small device footprint; only 30% compared to heat exchangers in the past, saving space for other uses.

- Compact and flexible structure; plates can be added according to heat exchange requirements.

- Excellent heat exchange efficiency; one unit replaces multiple traditional ones for lower operation costs.

- Lightweight; easy to disassemble for inspection and maintenance.

- Easy installation and easy piping.

- Long service lifespan; brief time requirement for annual maintenance.

- Strong resistance against corrosion; less prone to clogged plant. High availability of production line ensures a safe and trouble-free manufacturing process.

- Local (Taiwan) maintenance force and swift after sales service.

Semi-welded Gasket Plate Heat Exchangers advantage the customer to opt for Plate Heat Exchanger under harsh work conditions without the need to use traditional heat exchangers that use no gaskets.

This not only retains beneficial features of Plate Heat Exchangers – compact size, simple structure and high availability; but also overcomes the bottleneck in basic Plate Heat Exchangers that they cannot withstand high pressures and their gaskets are unable to resist specifically corrosive fluids.

Competitive product price saves purchase costs without compromising product safety.

High corrosion resistance also prolongs the service lifespan of the plant and saves maintenance costs.

Taiwan SRP Semi-welded Gasket Plate Heat Exchangers – Application Fields

- Petrochemical industry

- Chemical Industry

- Energy Industry

- Food industry and Beverages

- steel mill

- Paper and Pulp

- Marine

- HVAC and Refrigeration

- Water and Waste Treatment

1. Large refrigeration systems of the food and beverage industry

2. Highly corrosive processes of the chemical industry

3. High-temperature sterilization of pharmaceutical manufacturers

4. Refrigeration, air conditioning, and high-pressure refrigerant applications

5. Wastewater treatment and recycling of industrial processes

SPR Semi-Welding Gasket Plate Heat Exchanger – Customer success stories and case studies

Cooler of a Taiwan Nitrophosphate Fertilizer Plant using Semi-welded Plate Heat Exchanger

Issues

Production of the phosphate fertilizer requires cooling down nitric acid to obtain the required raw materials. Nitric acid of 65% concentration is highly corrosive; this hazardous liquid will corrode sealing gaskets of a basic heat exchanger.

However, the customer has limited space on-site for installing a traditional heat exchanger.

Application Solutions

The customer adopted Semi-welded Plate Heat Exchangers and installed a metal hood for its protection.

When equipment operates in the daytime, chilled water provided by a water chiller is used for cooling down the concentrated nitric acid.

Using Semi-welded Plates allows a smaller space for the installation and mitigates the risk of leaking concentrated nitric acid.

Material: Full 316L stainless steel

Processed water amount: 16740 Kg/H. Port DN100.

Working Temperature: 35℃-15℃ on the 65% concentrated nitric acid side; 12℃-18℃ on the chilled water side

- Compact and lightweight Plate Heat Exchanger may also be used in harsh conditions.

- Affordable price

- Much safer compared to other heat exchangers; easy to clean and maintain.

- Selection of the right materials eliminates the need for re-procurement due to corrosion of the product.

- No risks of liquid leakage.

- Multiple folds heat transfer efficiency than that of traditional heat exchangers.