Taiwan SRP Gas-to-Gas Heat Exchangers - Introduction

SRP Gas-to-Gas Heat Exchangers differ from traditional fin Heat Exchangers. New type Gas-to-Gas Heat Exchanger manufactured by Taiwan SRP Inc. features excellent heat exchanging effect and corrosion resistance. It also improves the hard to clean shortcomings of traditional air conditioners. High performance and lightweight. Small footprint required.

Taiwan SRP Inc. is the only supplier and manufacturer of plate type Heat Exchangers in Taiwan. Modular structure design allows a different combination of frames and plates based on actual needs for better scalability. SRP Heat Exchanger uses different structure materials to gain higher corrosion resistance or temperature strength for meeting requirements of different industrial applications, such as air pre-heater, desulfurization processor, boiler tail gas recycler, exhaust waste heat recycling, corrosive gas prevention, etc. at temperatures up to 950℃.

Features of SRP Gas-to-Gas Heat Exchangers

- Single metal seal

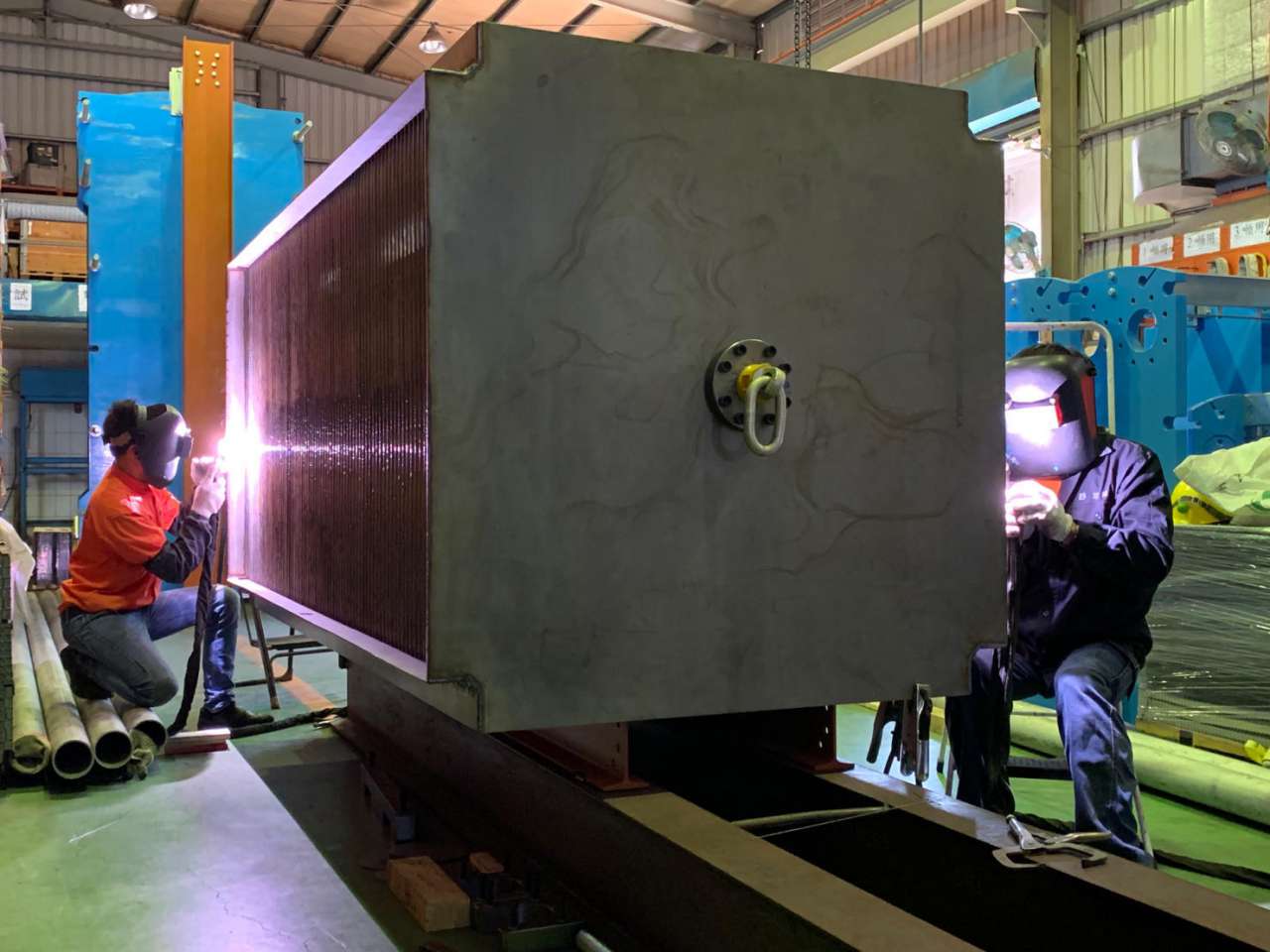

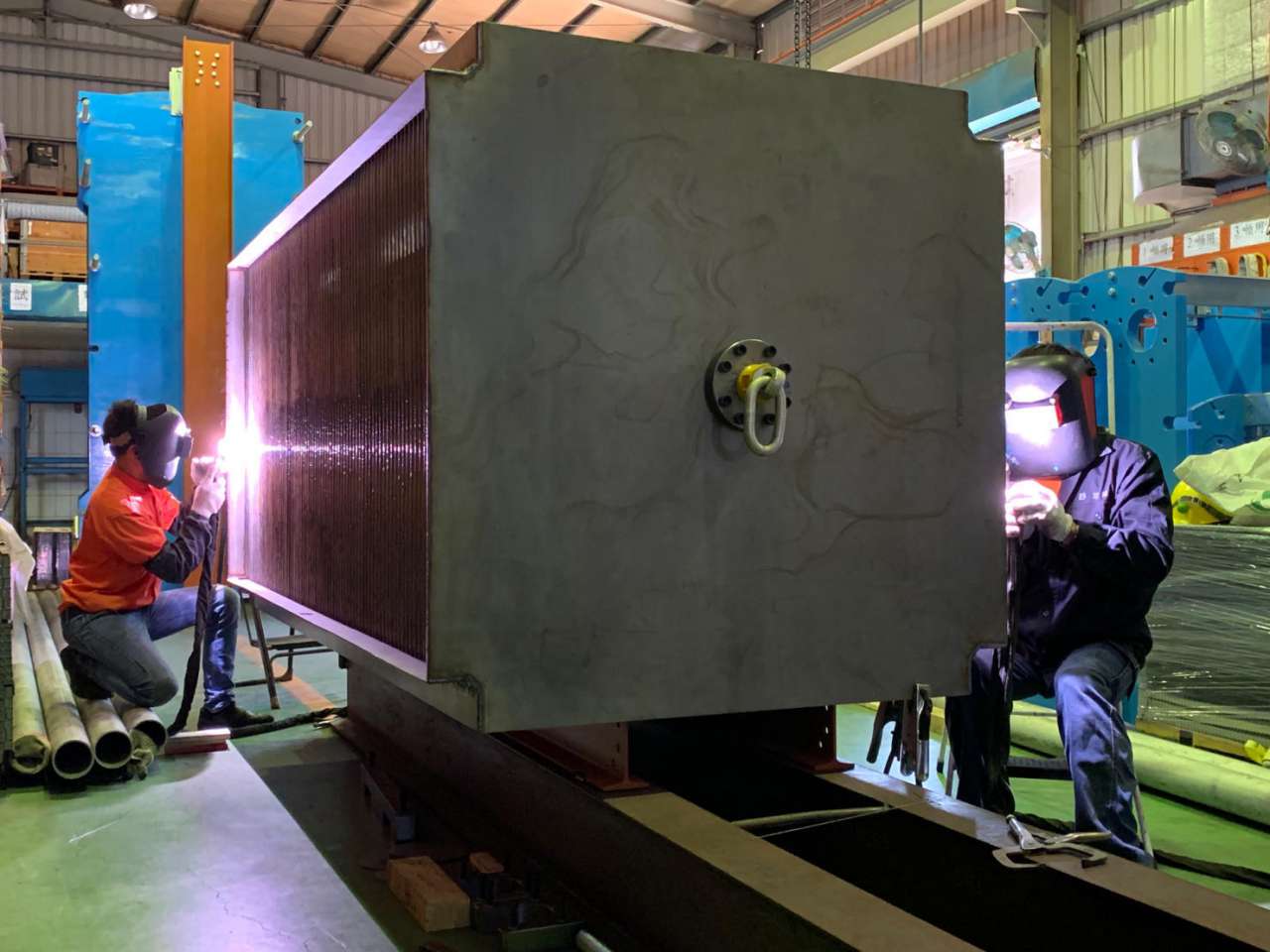

- Patented plate and laser welding; welds are of tight structure without miss points.

- Material can be of SS304/ SS316L/ SS317/ SS310/ SS904/ SMO254/ C276.

- Takes in all kinds of gases, including heavily polluted exhaust, high-temperature white fume, and sulfur-containing tail gas.

- Desulfurization process of stack tail gas

- High resistance against corrosion, long service lifespan. (Corrosion-resistant material)

- Modular Product Design with easy to clean channels.

- Maximum handling capacity up to 1,000,00/m³

- Low design pressure loss: 100PA-2000PA

Patented laser-welded channel plates as heat transfer elements. Special channel structure allows even distribution of gas in the channel and ensures excellent heat exchange effect.

Gas flow can be smooth and stagnation-free, eliminating gas stagnation and channel clogging problems often seen in traditional air conditioning systems.

Sealed Metal Housing for compact and hermetic product structure.

Customer Benefits through the use of SRP Gas-to-Gas Heat Exchangers

- Low pressure loss

- Resolve environmental pollution issues regarding exhaust gas and white fume; comply with statutory regulations

- Reduce air pollution control fee regarding discharge of SOX gases.

- Recycle gas for energy re-use. Power saving for the factory.

- Low scale formation and corrosion. Long service lifespan. Lowers purchase costs.

- Easy cleaning and maintenance. Ensures production line efficiency via stop-less operation.

- Lowers power consumption. Prolongs system lifespan. Reduces toxic emission.

- Competitive production cost

- Swift maintenance and after-sales service

- Modular design of product for high flexibility.

While environmental protection and green energy topics gain great concerns gradually and relevant legislation becomes more comprehensive, the discharge of corrosive and SOX gases in white fume exhaust from large scale stacks, sulfur-containing tail gases, boiler exhausts, and heavy oil combustion processes have created new issues in the industrial field.

For Gas-to-Gas Heat Exchanger products, Taiwan SRP Inc. offers applicable materials based on customer site conditions and flow demands. Users only need to clean as scheduled for achieving the spirit of a sustainable environment: one machine for a lifetime, renew energy from recycled heat. The recycled heat can also be used on the livelihood water of the factory or for secondary use of the site.

SRP Gas-to-Gas Heat Exchanger Applications

- Oil and gas industry

- petrochemical industry

- Chemical Industry

- Incinerator industrial

- Energy Industry

- Metallurgy Industry

(1) Pre-heat gas before combustion for improving boiler efficiency

(2) Exchange waste heat in the gas for energy saving

(3) Treat high-temperature gas before discharging it to the atmosphere for the protection of the ozone layer.

SRP Gas-to-Gas Heat Exchanger – Customer success stories and case studies

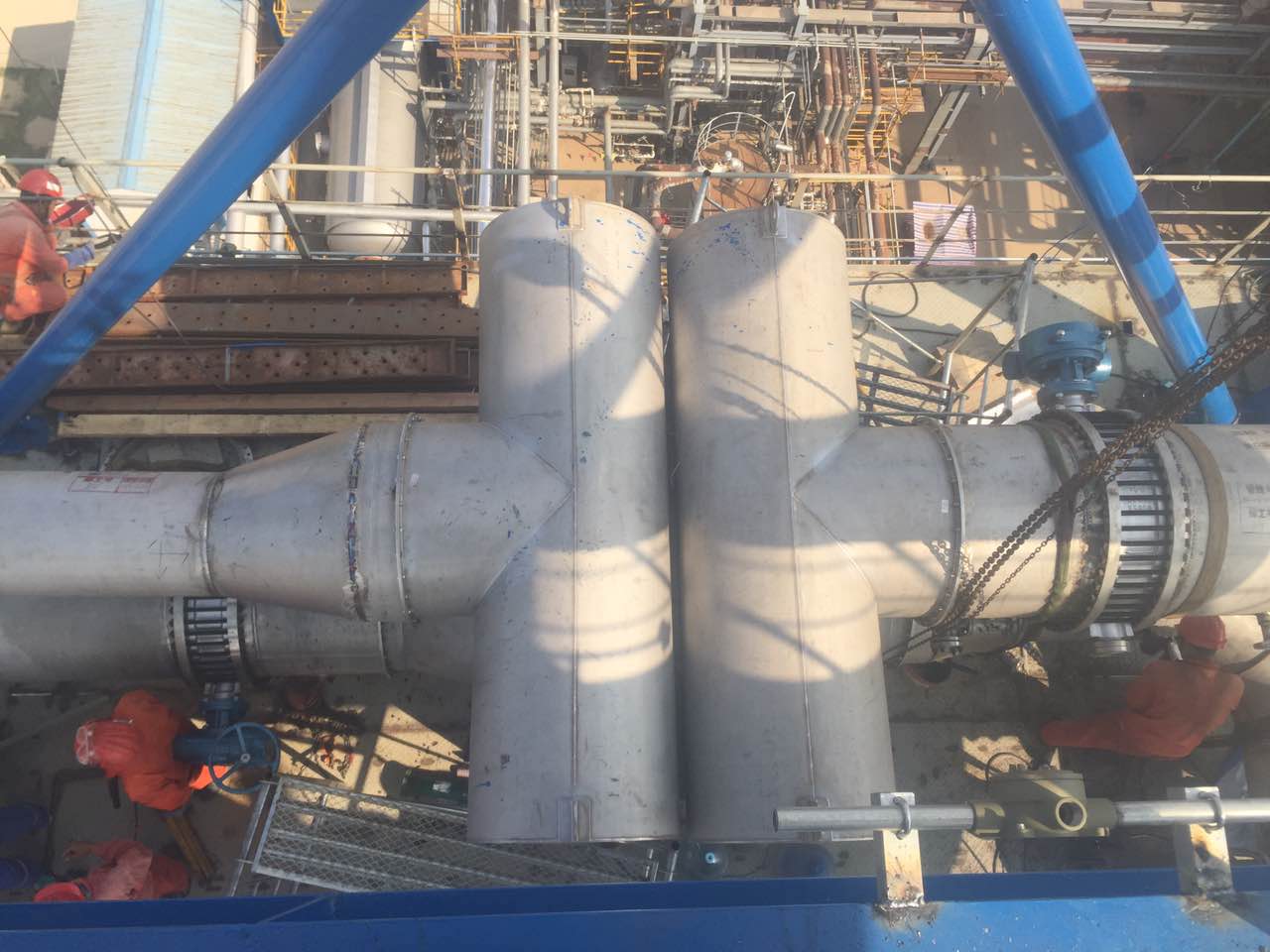

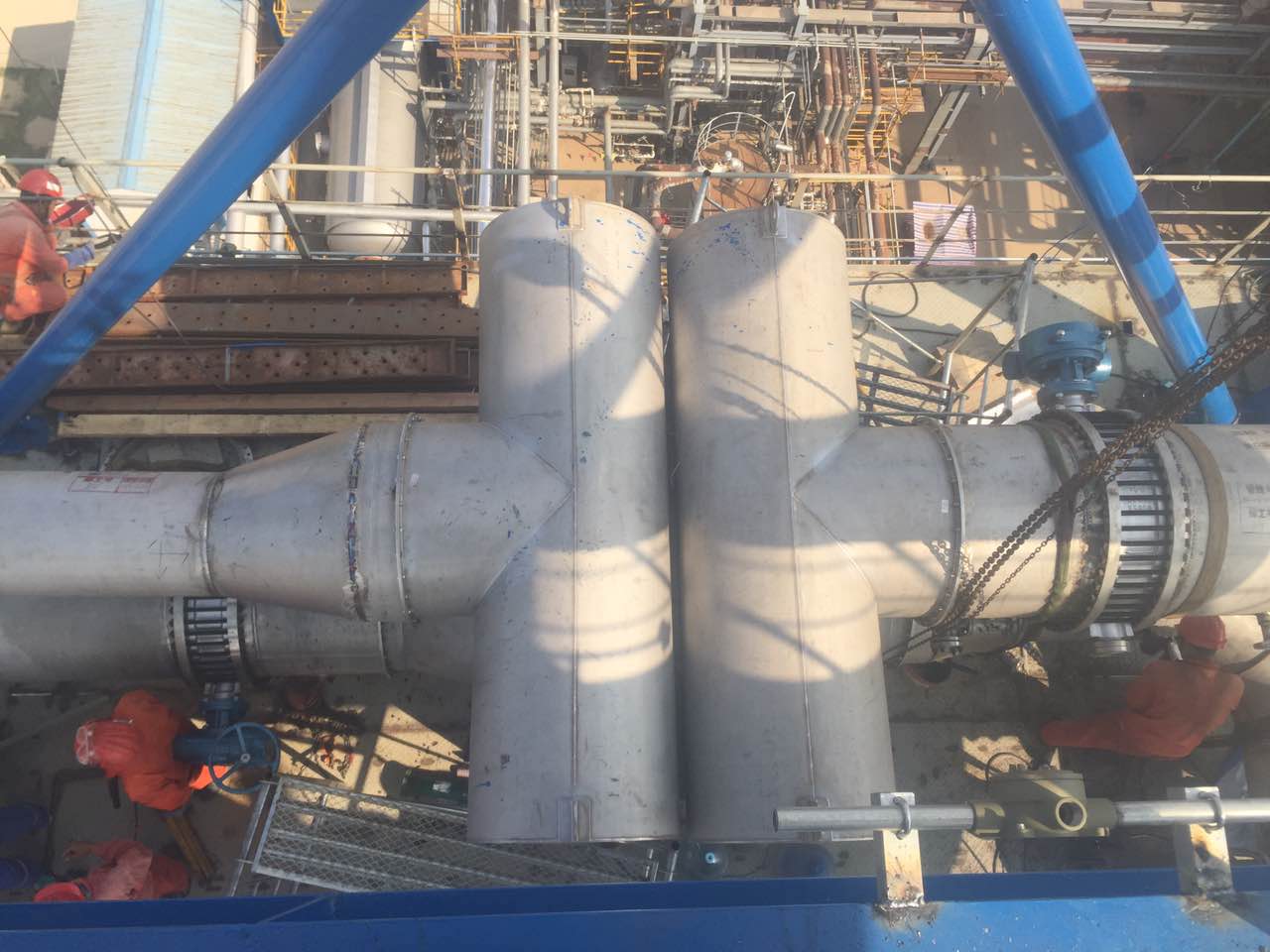

Gas-to-Gas Heat Exchanger for sulfur tail gas treatment segment of petrochemical industry, China

Issues

A large amount of sulfide-rich high-temperature gas will be discharged from the end of petrochemical processes. This will pollute the environment and lead to statutory fines.

Application Solutions

After installing our Gas-to-Gas Heat Exchanger, heat exchange between the existing high-temperature sulfur rich gas and the low temperature wet fume takes place before discharging the two into the atmosphere; this results in a temperature rise of the wet fume in the secondary side and elimination of its white fume, therefore reduced emission of SOXs.

Material: 316L full laser welded stainless steel. Handling gas flow: approximately 50000cfm/hr. Port Diameter DN1600. Considering dimension limitation during equipment transportation and convenience for installation and cleaning, equipment appearance is specially designed and optimized. The appearance design is patented.

Working Temperature: Primary side, 350℃-170℃; secondary side, 50℃-160℃.

- Compared to traditional Heat Exchanger, lighter weight and smaller volume for space-saving and easy installation.

- Customized based on the existing pipeline; the customer has no need to alter the existing pipeline.

- Compared to other Heat Exchangers, easy to clean, and no hoisting required.

- Proper material selected; no need for additional cost for procuring replacement parts due to corrosion.

- Ensures smooth operation of the production line without being affected by any equipment.

- Exclusive patented design of Taiwan SRP Inc.