Taiwan SRP Gasket Plate Heat Exchanger - Introduction

Use Proprietary Metal Plate as medium and special gasket as seal element.

Fluid flowing by the metal plate is channeled for heat exchange via a patented grove design on the plate. Model selection can be carried out based on site conditions. Nowadays, this product is widely used in industrial applications.

Compact structure design comprises the Frame, Plates, Gaskets, Tightening Bolts & Nuts, and other accessories.Evade shortcomings of traditional Shell and Tube Heat Exchangers that have large footprints and low efficiency in heat exchange.

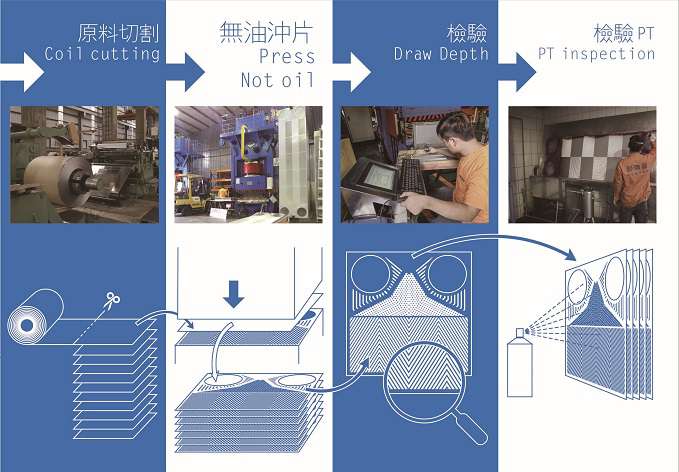

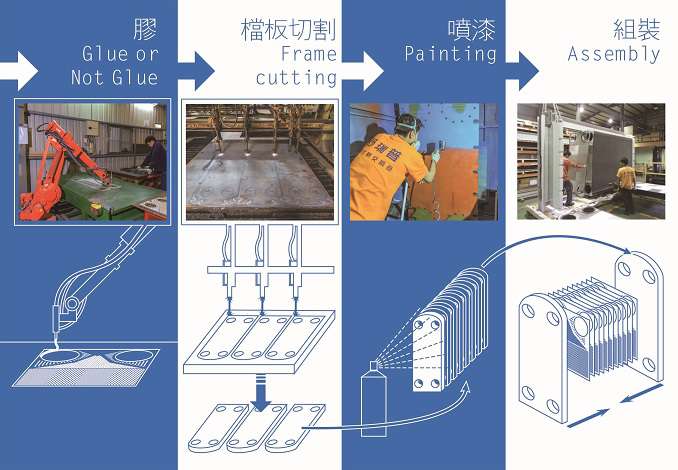

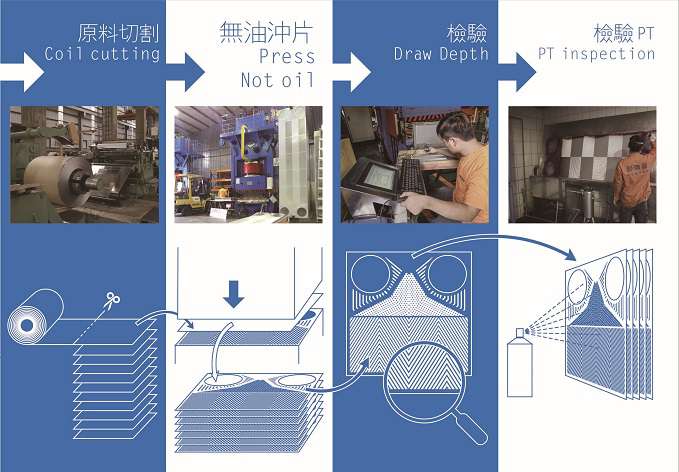

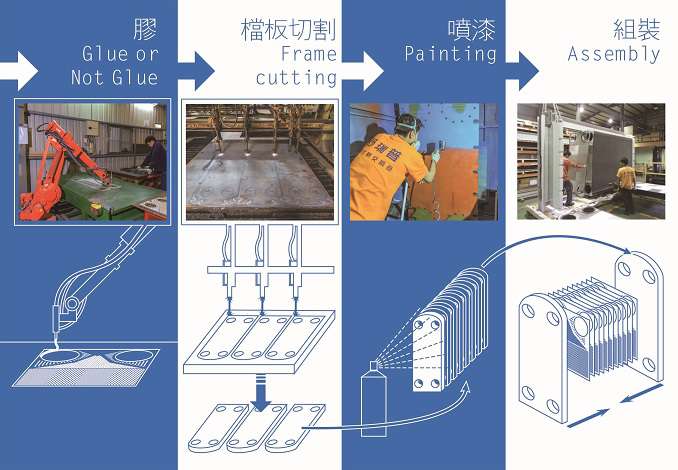

Merits include simple structure, small size, lightweight, and the highest heat-transfer efficiency in industrial heat exchangers.Taiwan SRP Incorporation is the one and only professional Plate Heat Exchanger manufacturer in Taiwan that provides one-stop services, including metal coil selection, fluid dynamics design, design drawings, manufacture, press, assembly, and after-sales services.

Taiwan SRP Gasket Plate Heat Exchanger, Features

- Small footprint, light weight; only 30% of that of traditional Shell & Tube heat exchangers.

- SRP plates provide a special Double Wall Design.

Two overlapping traditional plates are combined by laser welding at 4 corners to form a double-layer plate; this allows timely awareness from the external if one of the plates has a penetrating leakage. This design effectively lowers work-safety risks resulting from the mixing of 2 media. Double-plates are suitable for processes that strictly prohibit mixing process fluids, such as water for hospital use or cooling water for the pharmaceutical industry, food industry, chemicals, gun powder, and data centers.

- Simple Structure; easy to repair, maintain, and install.

- High heat-transfer efficiency; even distribution of fluids; less prone to scaling and clogging.

- Can be used as an evaporator or condenser.

- Minimum differential temperature of as low as 0.5°C.

- Taiwan SRP Inc. provides plates made of SS304/ SS316L/ SS317/ SS310/ SS904/ SMO254/ Hastelloy C276,Ti,Ti-PD; for strong resistance against corrosion.

- Low pressure loss

- Long service lifespan; with reserved space for expansion/curtailment of plates based on actual needs.

- NBR, EPDM, VITON, FKM, PTEF, Versatile gasket options for optimal selection based on requirements of customer fluids, ensuring strict sealing of fluids within the heat exchanger.

- One-for-all design for different purposes, especially for hotels, where water use can be adjusted alternatively for peak/off-peak hours based on different demands.

- A wide product range satisfies customers having different port diameters ranging from DN25 (1”) to DN500(20”).

- Diverse port selections.

- Suitable for fluids having high viscosity or corrosive properties (such as sulfuric acid).

- Made in Taiwan, short delivery time.

- Strict quality control of products and a well-experienced after-sales service team allow for shortened maintenance time.

Since its establishment in 1992, Taiwan SRP Inc. has been deeply devoted to servicing Taiwan and overseas markets with plate heat exchangers.With integrated operation procedures, we offer comprehensive, professional and prompt services, including order reception, interview, delivery, as well as subsequent maintenance and repair.

Taiwan SRP Inc. holds certifications including USA ASME U Stamp, EU Pressure Equipment Directive (PED), American Bureau of Shipping (ABS), Det Norske Veritas (DNV), China Classification Society (CCS) & China Corporation Register of Shipping (CR) of Taiwan, Lloyds ISO 9001-2015, and EU Welding Certification EN3834-3.Taiwan Type-I Pressure Vessel Codes and multiple international specifications are used for complying with review requirements and ensuring customer safety when using the device.

Customer Benefits through the use of Taiwan SRP Gasket Plate Heat Exchangers

- Small device footprint; only 30% compared to traditional shell & tube heat exchangers, saving space for other uses.

- Excellent heat exchange efficiency; one unit replaces multiple traditional ones for thorough heat recovery.

- Lightweight; suitable for high-rise building installation.

- Easy maintenance; Long service lifespan; brief time requirement for annual maintenance.

- Strong resistance against corrosion; less prone to clogged plant. High availability of production line ensures safe and trouble-free manufacturing process.

- Competitive costs in production and maintenance.

- Swift maintenance force and after sales service.

- Protect other facilities and prevent water contamination; prolong the lifespan of peripheral devices such as water chillers.

Major benefits of Plate Heat Exchanger: eliminate issues often encountered by traditional heat exchangers, such as space craving, low efficiency, and large temperature differences.

Traditional heat exchangers demand large footprints, which increase installation costs; they are also expensive to build. For achieving small temperature differences, a traditional heat exchanger has to impose harsh spatial requirements.

The compactness of Plate Heat Exchanger saves up existing room that can be planned for additional use, thereby diminishing land and floor costs. Low installation cost also lowers operation costs.

Low pressure drop and high corrosion resistance prolong the service lifespan of the plant and save maintenance costs; the majority of industrial applications nowadays.

Taiwan SRP Gasket Plate Heat Exchangers – Application Fields

- oil and gas industry

- Petrochemical industry

- Chemical Industry

- Energy Industry

- Semiconductor Industry

- Food industry

- Pharmaceutical Industry

- steel mill

- Textile Industry

- Marine

- HVAC

- Hotel, Schools, life water.

(1) Chills cooling water of industrial processes.

(2) Water for Restaurant, Hot Spring, School, HVAC and Swim Pool.

(3) High-temperature sterilization of food and pharmaceutical industries.

(4) Marine vessel engine cooler, seawater desalination plant

(5) Data storage of IT industry; cooling of the large cloud machine room

(6) Heat storage and heat recycling of industrial processes

SRP Gasket Plate Heat Exchanger – Customer success stories and case studies

Large-scale Plate Heat Exchanger used in data centers, Taiwan

Issues

Machine rooms of large-scale data centers require constant-temperature cooling for preventing data storage consoles from overheating and for saving power.

Application Solutions

A customer uses off-peak power to chill down cooling water at nighttime and store chilled water in a specific water tower for being used to cool down the machine room during daytime. This can reduce the daytime total power consumption of machine room, thereby saving power costs.

Material: laser welded full 316L stainless steel.

Water Treatment Rate: 1170000 Kg/H. Port diameter: DN300.

Working Temperature: Primary side 37.5℃-21.1℃; secondary side 20.6℃-28.3℃.

- Compared with traditional heat exchangers, light weighted and compact design for space saving and easy installation.

- Affordable price.

- Compared with other types of heat exchangers, easy to clean and maintain.

- Selection of the right materials eliminates the need for re-procurement due to corrosion of product.

- Ensures smooth process in the production line without affecting the operation of facilities.

- Multiple folds heat transfer efficiency than that of traditional heat exchangers.